Sound Power

Energy is most often perceived as a product of heat or light. Traditionally, man has relied on fire for energy. The Sun too is perceived as an energy source that powers the earth. Sound is another powerful energy source

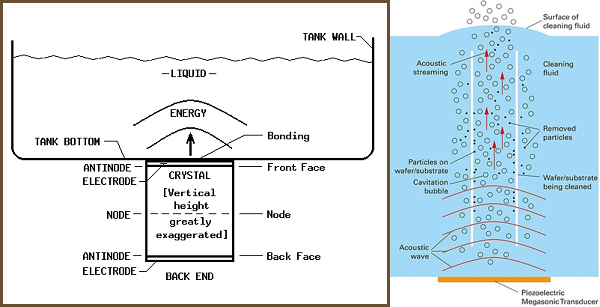

One of the latest techniques of industrial cleaning harnesses sound energy for the purpose. Sound waves of a very high frequency are known as ultrasonic waves. When these waves are directed towards an object placed in a fluid, its surface vibrates at a high frequency. With this vibration, flakes, rust, dirt, grease and other contaminants are dislodged from the surface. This leaves an ultra-clean surface.

Essentials of Ultrasonic Cleaning

Ultrasonic Cleaning has evolved as a process that is used to clean intricately designed objects. Limited physical access to complex surfaces requires the power of ultrasonic cleaning. So when we say “from clean to super clean” we mean microscopic cleaning that entails more than the eye can see.

Generator:

As the name suggests, the generator’s function is to generate high energy signals from electrical energy. The generator produces a wide variety of frequencies that might be used judiciously to meet a specific cleaning need.

Normal electricity is supplied at 50 or 60 Hz depending on the country. The generator converts this into high-frequencies ranging from 25 kHz, 40 kHz up to 1000 kHz.

Our ultrasonic cleaner is composed of three essential components:

- Generator

- Transducer

- Resonator

Transducer:

The Transducer converts electromagnetic waves into mechanical vibrations of the same frequency. Transducers use piezoelectric materials which convert an electrical signal into mechanical motion.

The transducers are mounted in water-proof cabins or outside the cleaning chambers. These vibrations are then transferred to resonators which ultimately drive the cleaning action.

Resonator:

The Resonator is a mechanism that moves at the same frequency as the transducer and creates waves with high and low-pressure areas in the fluid.

Resonators are always coupled with transducers and form the heart of the Ultrasonic system. Resonators are submerged and mounted inside the cleaning chamber.

There are essentially two types of resonators. Plate resonators and tube resonators. Tube resonators have a higher capacity (Watts) and a high efficiency in transforming sound waves into mechanical vibrations and offer a 360o coverage. These are vacuum proof and work even with solvent-based cleaning systems.

Ultrasonic cleaning is a complex but effective technique to ensure perfect cleaning. The quality and design of the components play a vital role in delivering optimal cleaning results that conform to internationally established standards.